Tantalum is a chemical element with symbol Ta and atomic number 73. Previously known as tantalium, its name comes from Tantalus, a villain from Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. It is part of the refractory metals group, which are widely used as minor components in alloys.Tantalum is dark (blue-gray),dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity. The metal is renowned for its resistance to corrosion by acids; in fact, at temperatures below 150 °C tantalum is almost completely immune to attack by the normally aggressive aqua regia.

Tantalum Sputtering Target is produced by EB melting. It's usually applied for magnetic recording media, printer components, flat panel displays, optic, industrial glass, and thin film resistors. High purity Tantalum Sputtering Target is normally used for semiconductor application. Tantalum's high natural strength with its low thermal expansion coefficient, together with its ability to stick to both copper and silicon make it the perfect choice for a diffusion barrier to prevent copper and silicon from interacting.

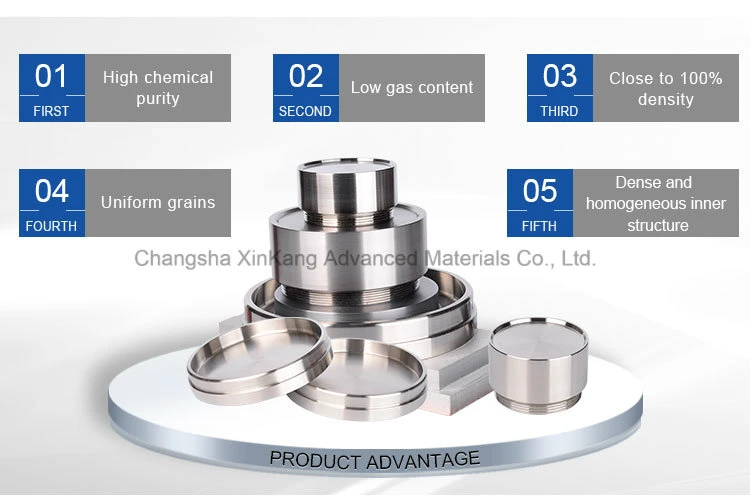

XK is a professional producer of Tantalum sputtering targets with various shapes and purity, which are mainly applied to semi-conductive & micro-electronics industry. Thanks to the special forming processes we used, our Tantalum sputtering targets possess higher density, smaller average particle size as well as high purity, as a result, you can benefit from a faster process due to higher sputtering speeds and obtain very homogeneous Tantalum layers.

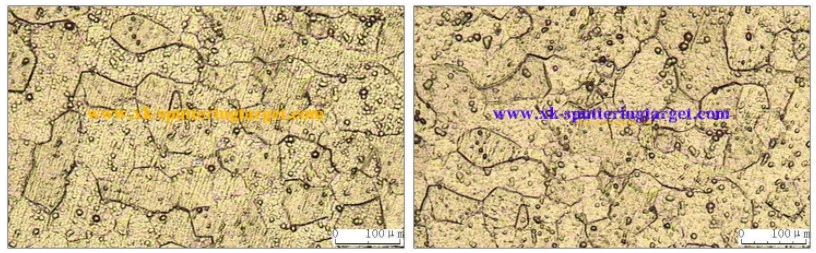

The flexibility of our production process allows to adjust the microstructure of our coating material to achieve your desired effect. If the grains of the sputtering target are uniformly aligned, the user can benefit from constant erosion rates and homogeneous layers. The picture below are two typical micrographs of our Tantalum sputtering target, the average grain size<100μm.

1. Analysis of metal elements using GDMS or ICP-OES;

2. Gas element analysis using LECO.

| Elements | Actual | Spec | Units | Elements | Actual | Spec | Units | Elements | Actual | Spec | Units |

| Li | ppm | Zn | ppm | Pb | ppm | ||||||

| B | ppm | Ga | ppm | Bi | ppm | ||||||

| F | ppm | Ge | ppm | Y | ppm | ||||||

| Na | ppm | As | ppm | Th | ppm | ||||||

| Mg | ppm | Se | ppm | Er | ppm | ||||||

| Al | ppm | Zr | ppm | Ru | ppm | ||||||

| Si | <1 | ppm | Nb | <10 | ppm | Rb | ppm | ||||

| P | ppm | Mo | <10 | ppm | Sr | ppm | |||||

| Cl | ppm | Pd | ppm | Sc | ppm | ||||||

| K | ppm | Ag | ppm | Be | ppm | ||||||

| Ca | ppm | Sn | ppm | Rh | ppm | ||||||

| Ti | <1 | ppm | Sb | ppm | Cd | ppm | |||||

| V | ppm | Ba | ppm | ||||||||

| Cr | ppm | Hf | ppm | ||||||||

| Mn | ppm | Ta | Matrix | wt% | C | 30 | ppm | ||||

| Fe | 1 | ppm | W | 33 | ppm | S | ppm | ||||

| Co | ppm | Pt | ppm | O | 68 | ppm | |||||

| Ni | 1 | ppm | Au | ppm | N | ppm | |||||

| Cu | ppm | Hg | ppm | H | 5 | ppm |

Related Products

Advantages

Application

Company Information

Production Process

Production Certificate

Company Exibition

Packing and shipping

Standard export packaging: Vacuum sealed package inside; export carton or wooden case outside

Shipment can be made by Fedex, DHL, UPS, TNT express etc. for gross weight ≤100KG;

For large shipment ≥100KG , shipping method will be discussed with you.

FAQ

1. Are you trading company or manufacturer ?

Xinkang: We are a professional manufacturer specialized in this field for over 10 years.

Iron Cobalt Alloy FeCo Sputtering Target

2: How long is your delivery time?

Xinkang: Shipment can be made in 5-7 days for those regular size, or samples , and 15-20 days for batch quantity.

Iron Cobalt Alloy FeCo Sputtering Target

3: Do you have MOQ ?

Xinkang: No, we support samples.

Iron Cobalt Alloy FeCo Sputtering Target

4: What is your payment method?

Xinkang: T/T in advance, Paypal , Western Union and etc.

Iron Cobalt Alloy FeCo Sputtering Target

Welcome to contact us at any time !