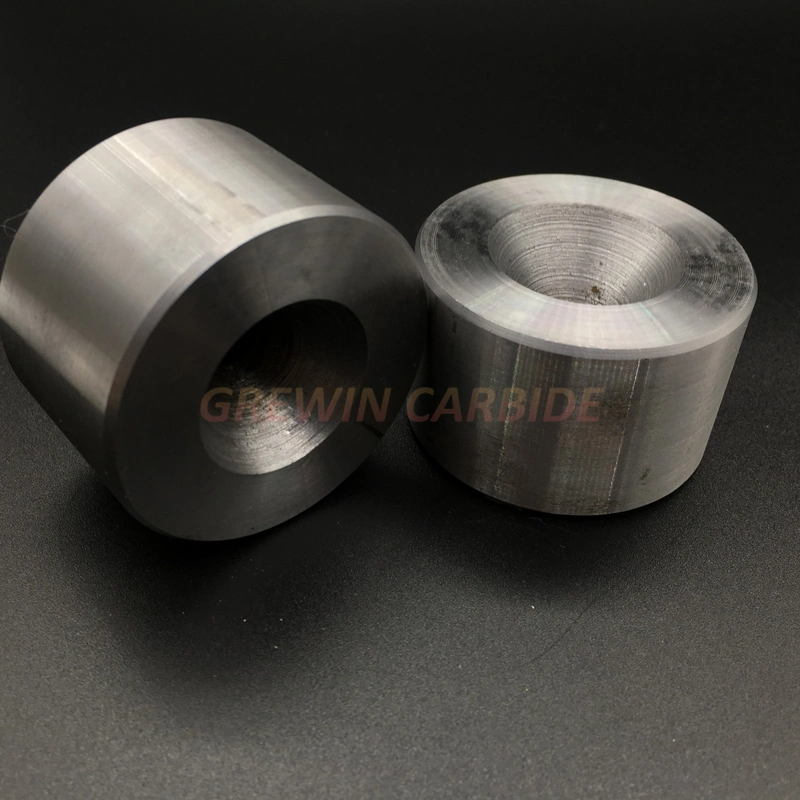

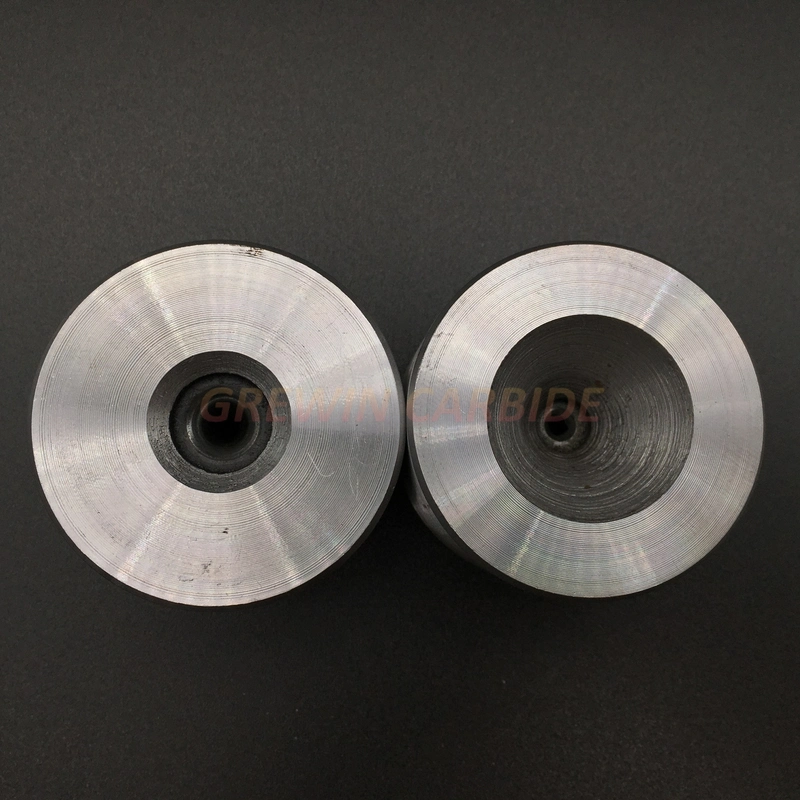

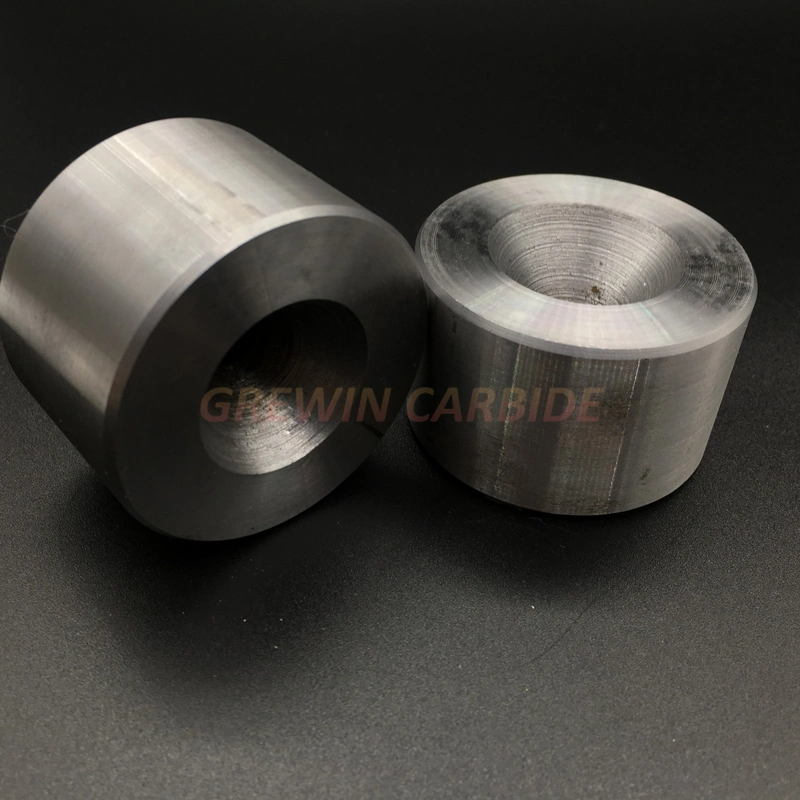

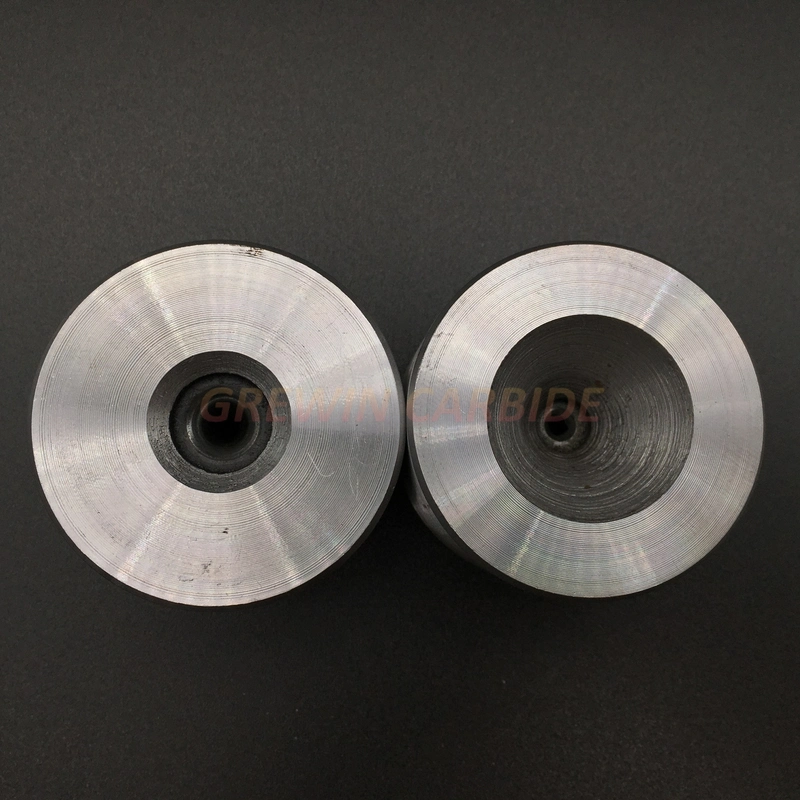

Solid Tungsten Carbide drawing Dies

Tungsten carbide Fasten punching mould has two definition: cold forging and hot forging.

it used on the cold forging machine, making the materials cutting, reforming, forming to the mould.

we use the advanced HIP sintering technology which makes the density perfect. It can make the working life longer and the punching resistant improves.

Advantages

1.The raw materials were choose strictly from the first step, the size of the WC is medium and course and the cobalt powder is imported one.

2.The advanced technology and machine will be used on low pressure sintering.

3.The HIP sintering will brings better density and strength, especially on working application is obvious.

4.special powder pressing technology with HIP sintering, reducing the porosity, improve the density and catachrestic.

5.we choose the suitable grade according to the exactly usage.

Carbdie wire drawing dies Grade

Tungsten carbide Fasten punching mould has two definition: cold forging and hot forging.

it used on the cold forging machine, making the materials cutting, reforming, forming to the mould.

we use the advanced HIP sintering technology which makes the density perfect. It can make the working life longer and the punching resistant improves.

Advantages

1.The raw materials were choose strictly from the first step, the size of the WC is medium and course and the cobalt powder is imported one.

2.The advanced technology and machine will be used on low pressure sintering.

3.The HIP sintering will brings better density and strength, especially on working application is obvious.

4.special powder pressing technology with HIP sintering, reducing the porosity, improve the density and catachrestic.

5.we choose the suitable grade according to the exactly usage.

Carbdie wire drawing dies Grade

| Grade | Density(g/cm3) | Hardness(HRA) | TRS(MPa) | Applications recommended |

| YG6X | 14.95 | 91.5 | 1800 | For drawing steel and nonferrous wires or bars of less than diameter 6.00mm under not so much stress. |

| YG6 | 14.95 | 90.5 | 1900 | For drawing steel, nonferrous alloy bars of less than diameter 20.00mm under more stress and also for drawing tubes of less than diameter 10.00mm. |

| YG8 | 14.8 | 89.5 | 2200 | For drawing steel and nonferrous bars and tubes, also for manufacturing mechanical parts, tools and wear parts. |

| YG10 | 14.5 | 88.5 | 2400 | |

| YG15 | 14.0 | 87.0 | 2800 | For drawing steel bars and tubes with a high reduction rate and for manufacturing anvils, drilling and punching and impacting. |