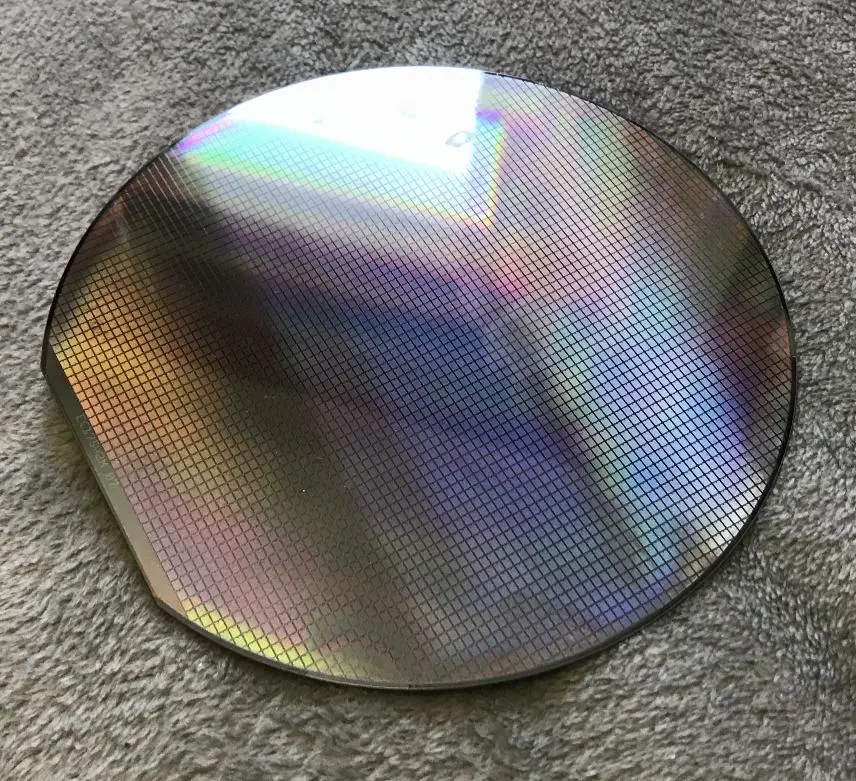

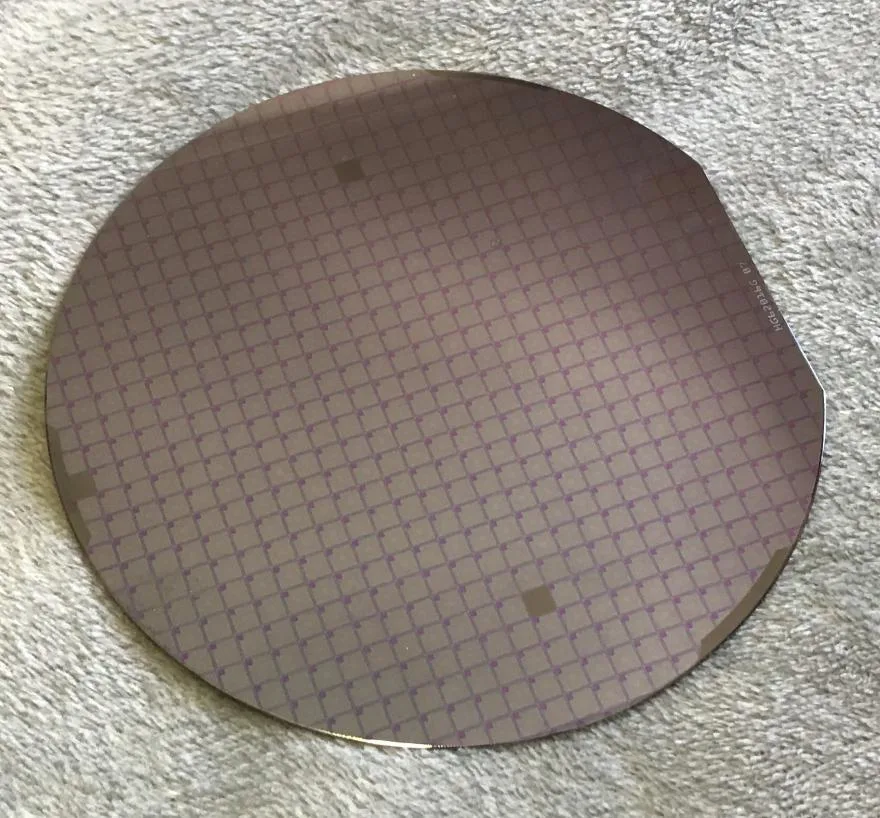

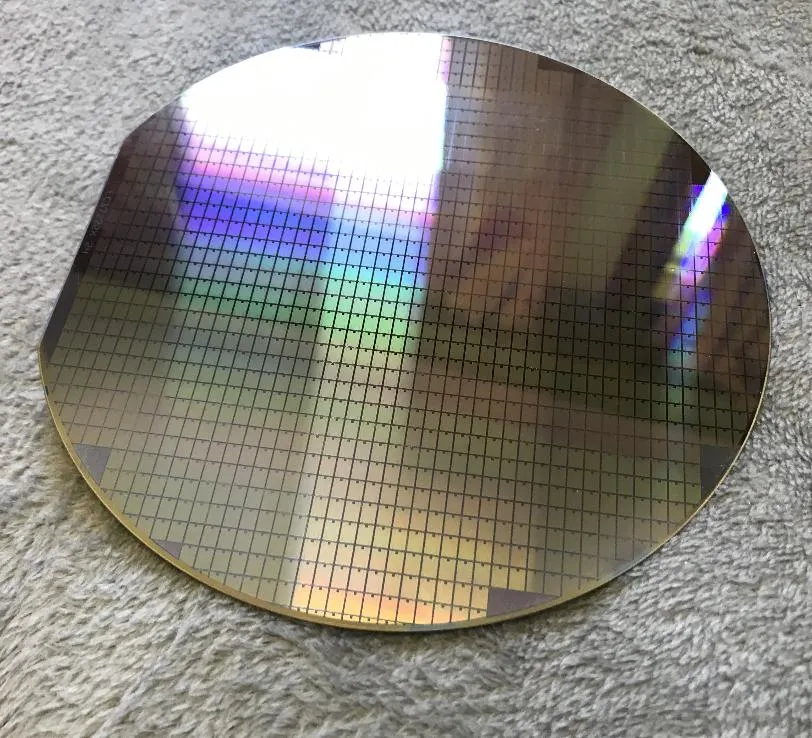

The original material of the wafer is silicon, and the surface of the earth's crust is endless silicon dioxide. Silica ore is refined through an electric arc furnace, chlorinated with hydrochloric acid, and distilled to produce high-purity polycrystalline silicon with a purity of up to 99.999999999%. The wafer manufacturing plant melts the polysilicon again, and then seed the seed crystal in the melt, and then slowly pull it out to form a cylindrical single crystal silicon ingot, because the silicon ingot is oriented by a crystal plane The determined seed crystal is gradually formed in the silicon raw material in the molten state. This process is called "long crystal". After the silicon ingot is cut, barreled, sliced, chamfered, polished, laser engraved, and packaged, it becomes the basic raw material of the integrated circuit factory-silicon wafer, which is called "wafer".

The finished silicon wafer manufactured by the chip is packaged as an IC after cutting!